Umbilical manufacture

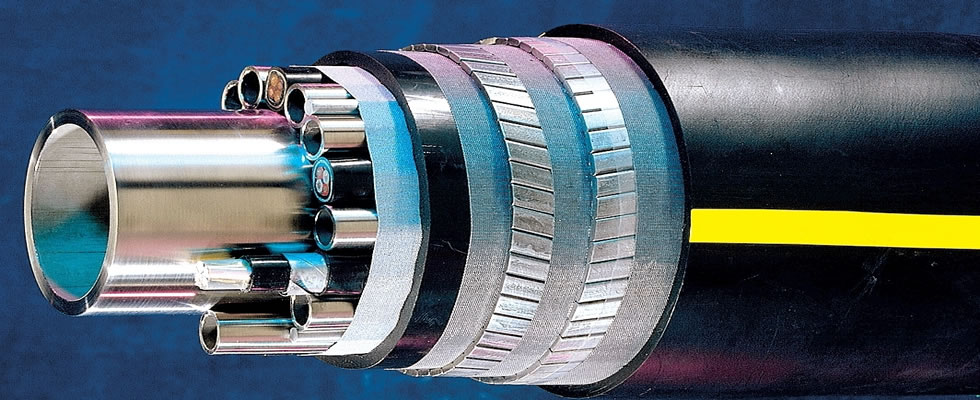

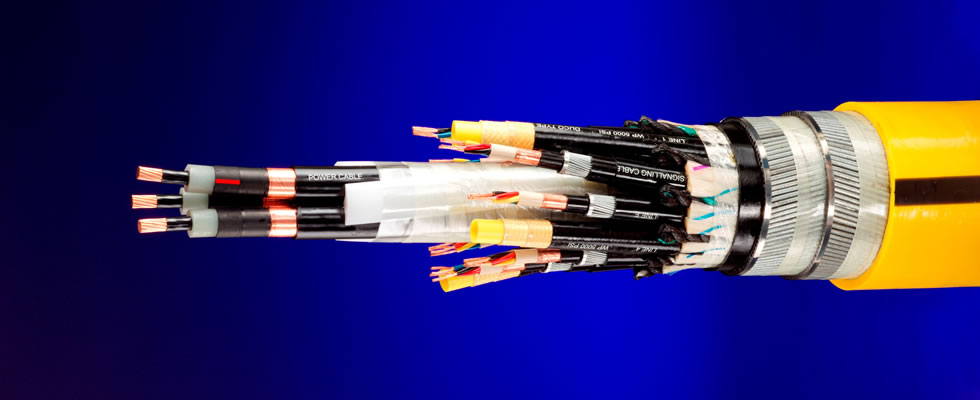

Umbilical manufacture commences with the production of the required functional components.

These are then bundled together using helical or reverse helix (SZ) lay up techniques.

This is followed by application of a protective sheath. Depending upon the umbilical design, layers of steel armour wires may be applied for mechanical protection, tensile strength or ballasting.

This is then followed by the addition of an outer sheath for overall mechanical protection.

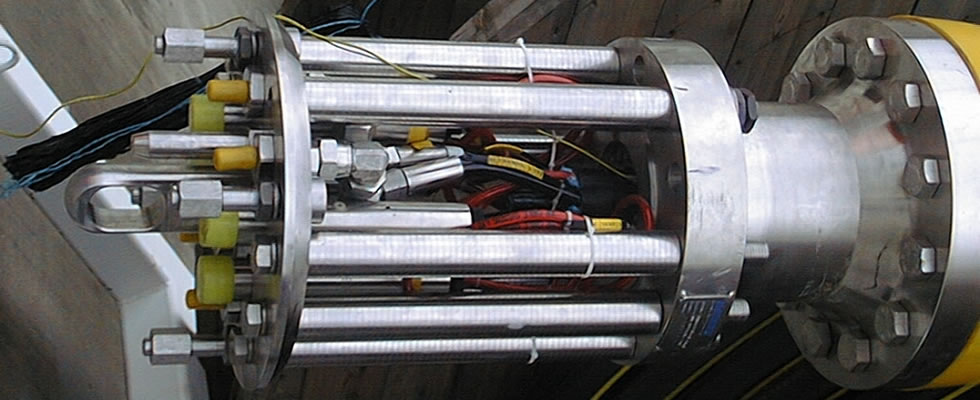

On completion of umbilical manufacture end terminations are fitted. After this the umbilical system is subjected to a test programme in order to confirm performance and integrity.

For new and/or unproven service a prototype length of umbilical may be produced and subject to a design verification programme.

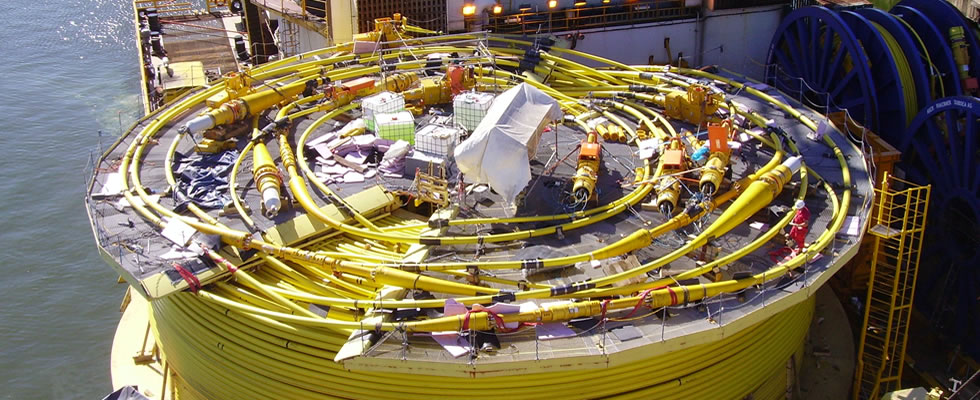

On successful completion, the umbilical system will then be delivered onto the installation / shipping vessel. Delivery can be either on reels or in the event of long/heavy umbilicals product will be loaded-out directly onto a carousel storage/deployment facility on the vessel.